- Home Page

- Company Profile

-

Our Products

- PTFE Sheets

- 3 mm PTFE Expanded Sheet

- PTFE Molded Sheet

- White PTFE Skived Sheet

- 6 Mm PTFE Sheet

- 1000 Mm PTFE Skived Sheet

- 600 Mm PTFE Skived Sheet

- 1200 Mm PTFE Sheet

- 600 Mm Skived PTFE Sheet

- 450 Mm PTFE Skived Sheet

- 300 Mm PTFE Molded Sheet

- 5 Mm Expanded PTFE Sheet

- 450 Mm PTFE Sheet

- Expanded PTFE Sheet

- White Expanded PTFE Sheet

- 3 Mm Thick PTFE Sheet

- PTFE Sheet

- PTFE Sheet 6mm

- PTFE Sheet 8mm

- PTFE Bushes

- PTFE Rods

- PTFE Tubes

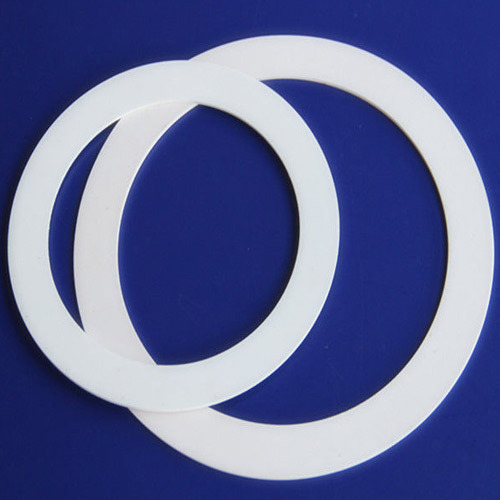

- PTFE Gaskets

- PTFE Machined Components

- PTFE Plate

- PTFE Washers

- PTFE Ball

- PTFE Bellow

- Turcite Sheet Roll

- PTFE Seals

- PTFE Bar

- PTFE Skived Sheet

- Teflon Sheets

- Teflon Rods

- PTFE O Ring

- Bridge Bearing Pads

- PEEK Rod

- PEEK Products

- PTFE Sheets

- Extra Links

- Contact Us

PTFE RodsPolytetrafluoroethylene is the short term of PTFE of our PTFE rods, which are the small components of machines, vehicles and allied materials. These allow the structures to function smoothly under numerous tough environments. CaF2 and fluorspar are the main material, which is derived from anhydrous hydrofluoric, to make these rods. The tetrafluoroethylene is fractioned and washed to expel numerous fluorocarbons and hydrochloric acid that is produced amid the pyrolysis procedure. In addition, the purified tetrafluoroethylene is polymerized in autoclaves with a liquid solution of peroxy catalyst or ammonium persulfate to make rigid and functional Polytetrafluoroethylene rods. The reaction of PTFE is exothermic and rapid; therefore, conditions should be carefully monitored. These rods have dimensional accuracy and orifices for correct attachment on machines. They significantly improve the working life while being resistant against chemicals, acids, water, oils, and more factors.

Key Features:

|

|

|

|

SANGHVI TECHNO PRODUCTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese